Blog Posts

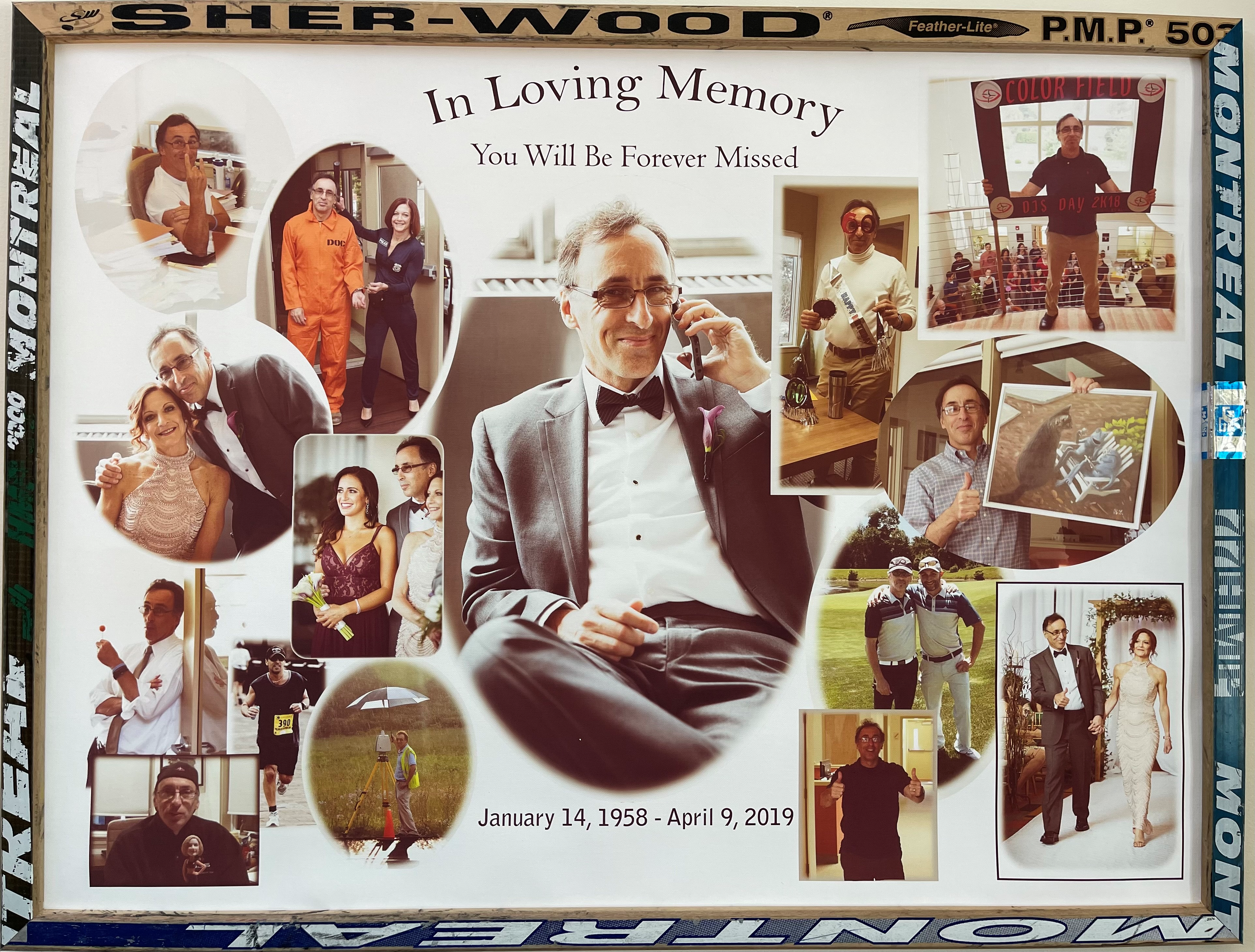

Reconstructing A Legend: Steve Schorr, In Memoriam

Five years after his passing, Steve Schorr’s legacy thrives through the continued success and expansion of DJS Associates and the impact of his leadership in the forensic community. Steve is…

How Weatherproof is Your Case Strategy?

Clients often approach forensic meteorologists after reviewing weather data retrieved from the internet and developing their own interpretation of the conditions on the date of an incident. Many times, the…

Cruise with Caution: Motorcycle Safety Awareness

Motorcycle Safety Awareness Month (May 2024) coincides with warmer weather as more riders return to the streets in regions where snow, ice, and cold weather conditions may have previously interfered.…

Teens, Trucks, & Traffic

Mitzi Hartman, Trucking Safety Expert with DJS Associates, is a driving force behind the Illinois Trucking Foundation’s Teens, Trucks, & Traffic event. This event is designed to reinforce and expand…

Fight or Flight: Analysis of an Aircraft Jump Seat

Case Summary: A flight attendant was seated in a forward-facing crew jump seat (L2) in the rear cabin of a commercial aircraft during a flight. She reported that as the…

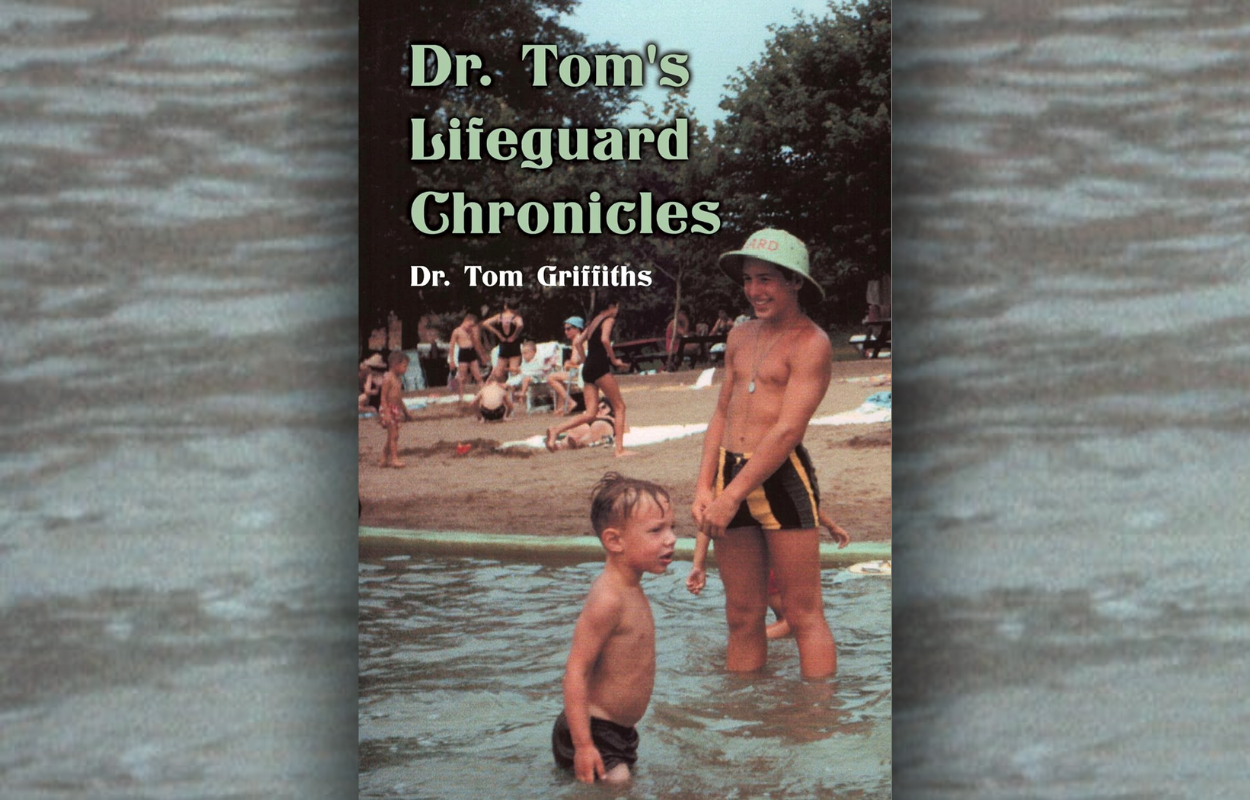

Dr. Tom’s Lifeguard Chronicles Book Release

Tom Griffiths, Ed.D., Aquatic Safety Expert with DJS Associates released his latest publication on March 30, 2024. Dr. Tom’s Lifeguard Chronicles intertwines nostalgic memories with case studies and other tales…

2024 PA Insurance Fraud Conference

On April 12th, DJS Principal Collision Reconstruction Engineer, Robert T. Lynch, P.E., and Mobile Forensic Analyst, Timothy R. Primrose, will be speaking at 2024 Pennsylvania Insurance Fraud Conference. Their presentation,…

NJAJ Boardwalk Seminar

DJS Associates, Inc. will be exhibiting at the New Jersey Association for Justice (NJAJ) Boardwalk Seminar 2024 at Harrah’s Resort in Atlantic City, New Jersey from April 17th – 19th. …

The Dispute Resolution Institute’s Personal Injury Potpourri

Justin Schorr, Ph.D., and Michael van der Veen, Esquire, will join an esteemed faculty of legal industry leaders at the Dispute Resolution Institute (DRI) Personal Injury Potpourri on April 18th. …