Blog Posts

NJICLE “A Day on Evidence” Seminar

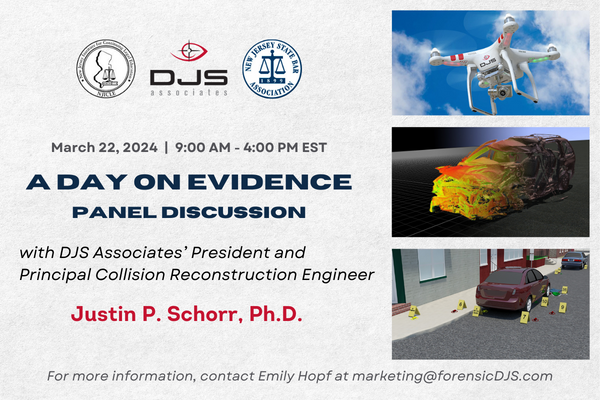

On March 22nd, Justin P. Schorr, Ph.D., President of DJS Associates will join a panel of legal industry leaders for the New Jersey Institute for Continuing Legal Education (NJICLE) “A…

NASP 2024 Spring Conference

Principal Collision Reconstruction Engineer with DJS Associates, Robert T. Lynch, P.E. will be presenting at the National Association of Subrogation Professionals (NASP) 2024 Spring Conference on March 21st. His topic,…

Trampoline Park Misses the Mark

Case Summary: Plaintiff was 14 years’ old when he visited Defendant’s trampoline park with his family. Intending to jump into a foam pit, Plaintiff inadvertently jumped from a raised platform…

Falling Barrier Pin Impales Vehicle

Case Summary: The barrier pin was a steel rod 1-inch in diameter, 16 inches long, and weighed 3.5 pounds. It was being used to secure a temporary barrier to the…

Sample Size CBD Cream, Full Size Fiasco

Case Summary: Plaintiff was given a sample size jar of a cream containing cannabidiol (CBD) oil at an exhibition show. The cream was to be applied topically, for relief of…

Driveshaft Failure

Car outer joint, driveshaft and control arm close-up. Inspecting a used front wheel drive vehicle by Ivan Radic is licensed under CC BY 4.0 Case Summary: The right front passenger…

Rash Resort: Lazy River, Negligent Records

Case Summary: During the busy Memorial Day Weekend, a three-year-old boy visiting a large beach front resort in North Carolina received severe chemicals burns to his upper legs, thighs, and…

Venmo Transactions Reveal Alternative Timeline

Case Summary: A fatal incident occurred in a small town when a young man left a local bar and was later found deceased following a single-vehicle crash on a back…

“Elder Abuse and Neglect” CLE Webinar

Stacy Donnelly, RN, BSN, Nursing and Nursing Home Expert with DJS will present the complementary CLE webinar, “Elder Abuse and Neglect,” on March 5th. While these are difficult topics to…