Rifle Occluded Barrel Shooting

,

Stephen A. Batzer, Ph.D., Materials Science Consultant ::::

Case Synopsis: A man and his teenage son were on a backpacking trip in the mountains. They brought with them a break-action single shot rifle for plinking. The rifle was a brand new, caliber .22 Magnum rimfire. They had never fired the weapon previously. At their initial camp site, the young man took the rifle to shoot at a target. He loaded a round, sighted the rifle, and pulled the trigger. The rifle exploded, causing temporary partial blindness and facial markings.

Analysis: During the shot, the base of the brass cartridge case separated, and hot propellant gas and molten brass sprayed backwards into the young shooter’s face. The insufficiently contained cartridge explosion destroyed the rifle’s action, making the rifle unsuitable for a later test shot. The defendant, manufacturer of the rifle, stated that if the young man had been wearing safety glasses he would not have received any injuries, and the manual indicated the recommendation for safety glasses. The plaintiff countered that no injuries would have been incurred if the rifle was suitable to its intended function. Further, the manual did not provide a fair warning that the rifle could explode during the first shot. The defense also indicated that the rifle was known to be safe as it had been proof tested by test firing in Italy prior to export to the United States, and that proof marks on the rifle’s receiver and barrel attested to the incident rifle’s proven safe design.

The ammunition was preserved and examined. It consisted of factory-loaded rounds, not hand-loads, and therefore the ammunition was presumably safe. Each remaining cartridge of the container was visually examined and weighed. There were no irregularities noted. The rifle was visually examined and photographed. No obstruction was present in the bore. There were no obvious manufacturing defects, indicating that further and more sophisticated examination techniques were necessary.

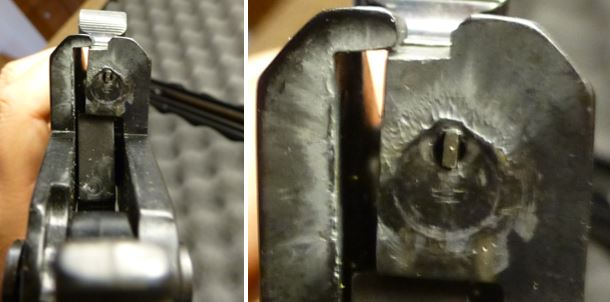

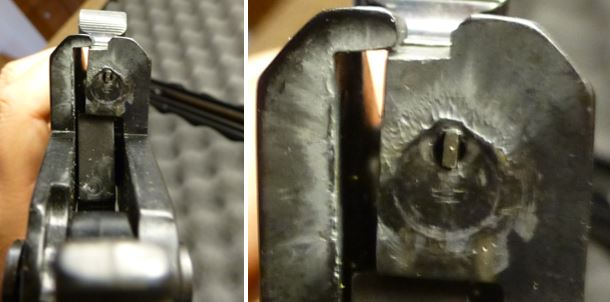

The rifle was jointly examined by the defendant’s and plaintiff’s experts at a neutral test laboratory. A variety of techniques to include microscopic and X-ray analysis were employed. Since the action was severely deformed, no headspace measurements using chamber gages were performed. However, by using a borescope, a circumferential ring was found in the interior of the barrel at a position several inches aft of the muzzle. It is therefore likely that a barrel obstruction caused a sufficiently severe bore pressure spike such that the breech face moved rearward relative to the barrel chamber. With a distorted receiver, the cartridge case was partially unsupported and the base of the cartridge casing separated. The result was hot gases and molten brass discharging rearward. A photograph of the breech face, along with a closeup, is set forth below.

The bore obstruction was temporary, as the bullet fired by the plaintiff pushed the obstruction out of its path. The defendant claimed that the obstruction was probably caused by, or at least should have been detected by, the shooter himself. Thus, this was a preventable accident which was totally the responsibility of the shooter. The plaintiff’s position was that rifle was not dropped into the soil, which would have left an obstruction witness mark directly at the muzzle, not inches before the muzzle. Further, no patch had been inserted into the bore to clean it, and therefore, as the rifle was brand new, there is no way that the obstruction of the bore was caused by the new owners.

It was apparent from the circumstances of the incident and the witness marks within the barrel’s bore that the test firing of the rifle that occurred in Italy prior to the weapon’s export had gone terribly wrong. A “squib” load had been fired. That is, one without sufficient (or any) gunpowder propellant, only primer. The test round bullet had not exited the bore and was lodged within the barrel at the time of the rifle’s retail sale. The manufacturer did not realize that the test shot that was used to validate the safety of the rifle had actually caused the rifle to become defective.

Stephen A. Batzer, Ph.D., Materials Science Consultant with DJS Associates, can be reached via email at experts@forensicDJS.com or via phone at 215-659-2010.

Tags: Materials Science Consultant | Stephen A. Batzer