Is The Sum of the “Parts” Greater than the Whole? Responsibility in Manufacturing.

Many vocational trucks distributed throughout North America are not manufactured, start to finish, on a single assembly line. Rather, many small, medium, and even some large trucks are manufactured in…

Vehicle Repair Industry Standards Exist for a Reason

R. Scott King, BSME, Principle Automotive / Mechanical Engineer :::: Vehicle repair industry standards exist primarily to promote the safety of the women and men that service passenger vehicles and…

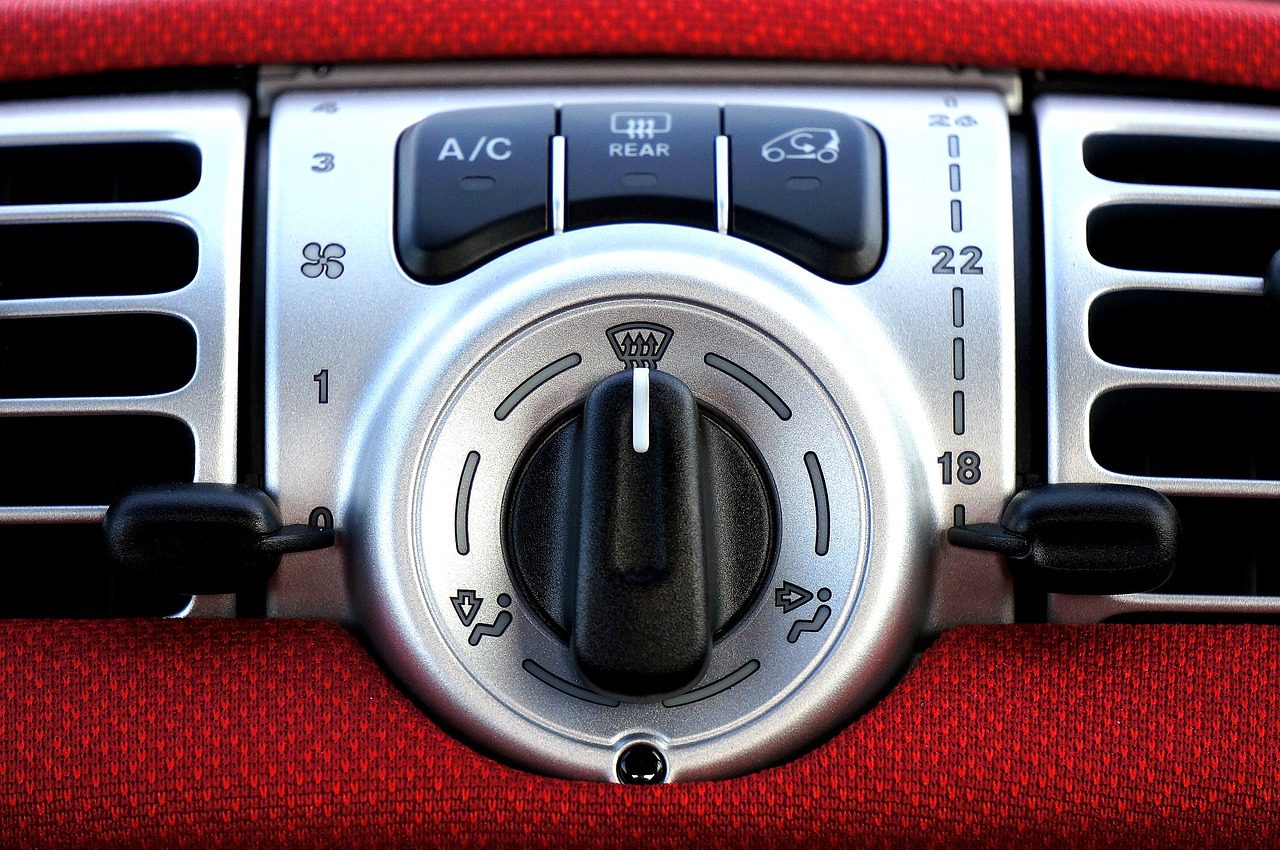

BMW HVAC Blower Wiring Recall

R. Scott King, BSME, Sr. Automotive / Mechanical Engineer :::: Earlier this month, BMW announced it is recalling over 600,000 3-Series vehicles manufactured between 2006 and 2011 over concerns of…

Obstructive Sleep Apnea and Commercial Vehicles

R. Scott King, BSME, Senior Automotive / Mechanical Engineer :::: The Federal Motor Carrier Safety Administration has decided to withdraw a March 2016 Advanced Notice of Proposed Rulemaking (ANPRN) related…

Forensic Investigation of Automotive Lights

R. Scott King, BSME, Automotive / Mechanical Engineer :::: For many years, automotive crash investigators and engineers have utilized light bulb filament analysis as a means to determine whether a…

Recall Update – Autonomous Technology

R. Scott King, BSME, Automotive / Mechanical Engineer :::: Completely autonomous (self-driving) vehicle technology may not be ready for today’s automotive market place owing to the numerous complexities of vehicle…

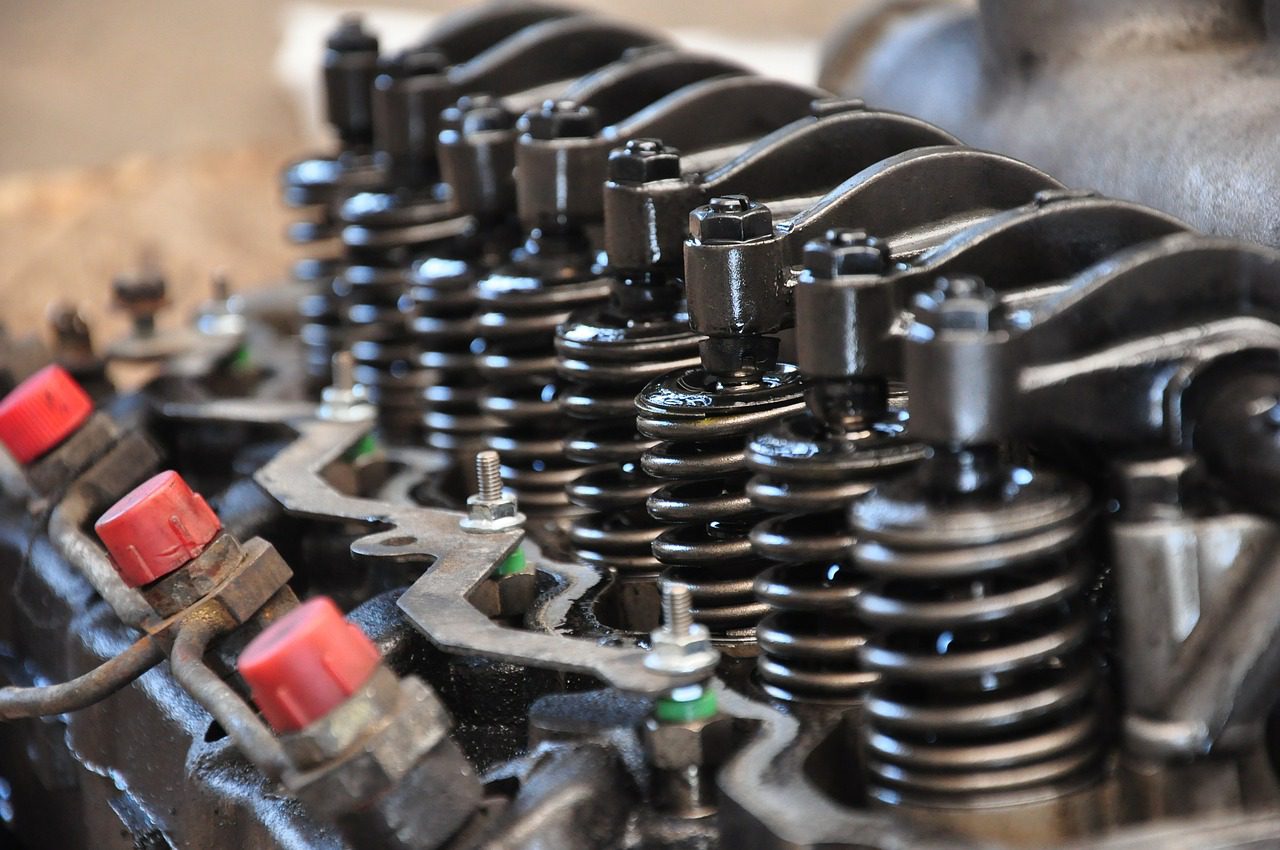

What’s That Ticking Sound in My Engine?

R. Scott King, BSME, Automotive / Mechanical Engineer :::: As consumers of automotive repair services, we know that from time to time a mechanic might not always fix it right…

Industry Update: Electronic Logging Devices in Commercial Trucks

R. Scott King, BSME, Automotive / Mechanical Engineer :::: In March 2017, we provided an industry update on a December 2016 ruling mandating the use of electronic logging devices (ELDs)…

Automotive Air Conditioning Systems

R. Scott King, BSME, Automotive / Mechanical Engineer :::: The automotive air-conditioner is a marvelous example of a simple system relying on the complex properties of the refrigerant within them.…