2024 Seminars and Webinars

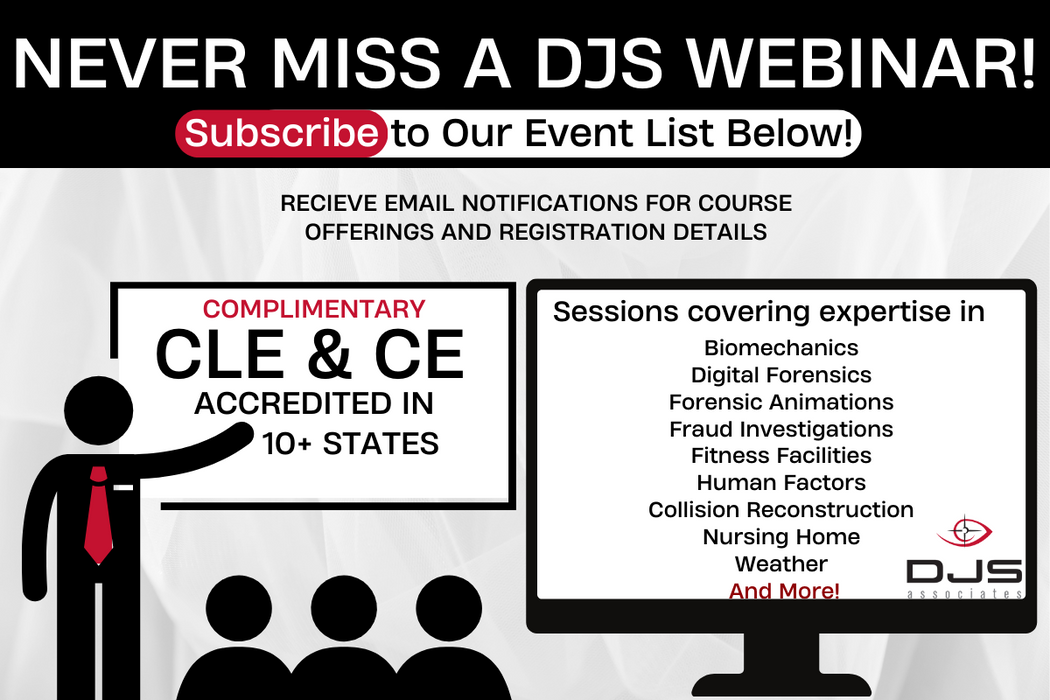

Receive email notifications regarding upcoming complimentary CE and CLE events by subscribing to our event list. Staying ahead starts with staying informed - we look forward to keeping you up-to-date…

DJS Safety Pup: Pursuing All Leads

DJS Associates, Inc., is proud to announce the newest member of our crew, Ellie! As our newest safety and security team member, Ellie brings boundless joy and a keen sense…

Tesla’s “Fundamental Flaw” and California’s 2022 Autonomous Vehicle Mileage & Disengagement Report

The past week has brought two important pieces of news in an otherwise quiet world of Autonomous Vehicles. First, California released the 2022 disengagement reports and Tesla was forced by…

Curing Mold Maladies in a Healthcare Setting

Case Description/Summary: Over a period of several years, in patient rooms, an acute care healthcare facility experienced condensation forming on metal window frames, water dripping from soffits, and water-damaged gypsum…

Patient Hand-Off Communication

Stacy L. Donnelly, RN, BSN & Christa A. Bakos, RN, CWCN, DAPWCA What is Patient Hand-Off? Patients in healthcare facilities commonly receive care and treatment from a team of medical…

Throwing Shade: A Fallen Tree Canopy 3D Reconstruction

When a tree fell on a roadway, injuring a passer-by, DJS was tasked with analyzing the evidence to provide opinions on the measurements of the tree and extent of its…

Family Awarded $20.7M in 2018 Myrtle Beach Drowning Lawsuit

The family of 2018 tourist, Zurihun Wolde was awarded $20.7 million by the jury in a lawsuit against Lack’s Beach Service and lifeguard, John Doe. Aquatics Safety Expert with DJS…

Child Passenger Safety Week

September 18th to 24th is Child Passenger Safety Week, a time to make sure children are traveling safely. Every year, motor vehicle crashes rank high on the list of leading…